I have been messing about making a couple of simple items in the shop. I made a small cabinet to hold the TP in the main bathroom, and put on a door that resembles a picket fence. I also made a little wheeled cart for Missus to use at her looms, to hold rolls of fiber and her shuttles and such; oh, AND her coffee! There has always got to be a place for coffee near!

I also have doe a thing. I finally ordered a lathe. I went for one that was mid-sized, and would allow an extension to allow me to do the larger items I foresee me turning, and yet it is small enough to work the tiny things that mill likely consume most of its work. It can also turn bowls on the outside of the bed, so it is very versatile. I am hoping it will do for everyone in the family who could come by and learn on it, and for everything we could possibly want to own a lathe for! I have cleaned up a space in the sop for it, and ordered all the tools I need to get started, and all the accessories it needs to do all of that expanding I just talked about.

Now the only problem is getting the damned thing. I ordered it from Woodcraft, who has a store conveniently located just down in Salt Lake City, so they shipped it from a store in West Virginia! Okay, what do I know about their inventories? The carrier picked it up soon after, and carried it all the way to Chicago, where it is now sat for the third day in the back of the wagon while they look for a new horse to replace the one that apparently died on the last leg of the journey. I guess nobody has horses for sale in Chicago. They will probably have to have one shipped fresh from West Virginia. A call to customer service resulted in only a pleasant conversation with a vibrant young ladies voice, and what sounded like an angry memo attached to the parcel.

When it DOES get here, I will have every accessory already here, except for the way over-priced lightning, and the assortment of chucks and safety equipment that will make their needs apparent soon after I start using the lathe. I’ll try to get that stuff sorted out as soon as I understand what I actually need, and in the latter case, before I need to order teeth from West Virginia, too, or from a dead horse in Chicago, which ever is convenient and expedient.

In the mean time, I also am eyeing up some devices that will allow me to add threads to a dowel and hopefully eventually make my own work bench and vise. I have noticed in the woodworking book I have been reading, from 1887, that the first things students made were components to use on a bench, such as bench hooks, and mallets and the like. One of the first things I plan to turn on the lathe will be a mallet! Buy one tool, make several more! That is the way of it! There are a few more hand tools to get, but I have got a good start! I still really love the quiet of working with them. I have a few power tools to accommodate my needs in areas such as routing, straight sawing, and rounding edges and the like. I can even make box joints and dovetails, but it is turning out to be less confusing and just as easy to make them by hand as it could be to figure out the jig, and the router bits and setting, and how to properly position the wood in the jig, and hope that it all goes right when the power goes on! I am preferring the small router for freehand writing on the surface of the wood, over using it with the cursed jig!

At this point, the next things I would get if money were no object is a band saw, a better table saw, and a mill. The mill could be one of those small Wood-Mizer jobs, that only run around $3K. That is what will really up my potential wood supply, and from thence, wood working ability. Put that in my grubby little fingers, and the limit to what I could do is my imagination, and how much I can lift onto that saw!

But I could make do with the table saw I have got for a while!

When I reached 50, I could not believe I was there! Half a century old! I never really expected in my youth to make it! That’s old, I thought! Now I am here, I am thinking that I better hope this is only the half way mark! I have got a lot to do still! I have slowed down a little, but I think if I keep working at it, I can maintain the pace for a while to come. I have got to. There is a lot to do still!

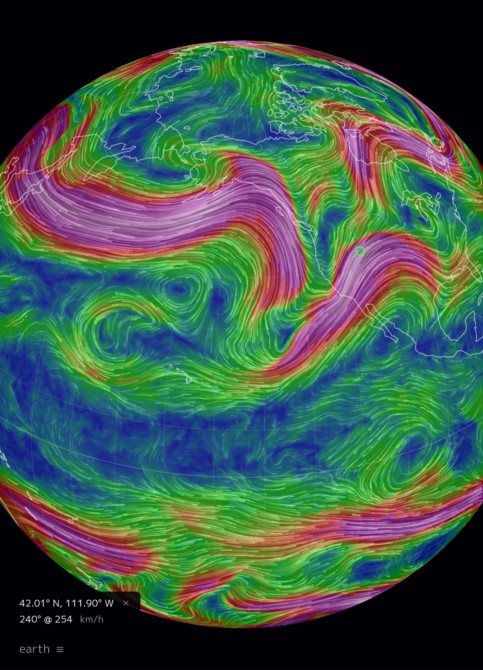

Day before yesterday I was up on the roof cleaning the chimney. I got the top 13 feet brushed out, and the spark arrestor cleaned up. I stopped there as my grandson was over, and I did not want to spend all the time up on the roof, nor down in the house dealing with the mess made by the bottom nine feet of pipe from the wall to the stove. Looks like next week we will be burning the stove though! It is a little early this year, but the jest stream will drop south of us very soon, and the weather we have got right now, rainy, is because of the leading edge of that dip bringing moisture up from the Pacific.

Look closely and see the little green circle in the purple band on the US, to see where we are at. The image depicts upper level winds, which have just about the greatest effect on our weather of anything else I have found, apart from the actual seasons. The weather goes as the wind blows. When the jest stream is south of us, it is cold here. When it comes up from southern California, it brings rain. When it is north, it is warm, and almost always sunny. It moves southward during the winters, when the season is cold. In the summer, it is chased back up to the Arctic. Forecasters are far more nuanced than I am, but I can pretty much guess what’s coming based on the website.

It is morning. The kids are up now/ I best get going and start my day! Grandson spends the night tonight. I should probably get that stove pipe cleaned up before he gets here, to avoid the time crunch of getting it done after he leaves, and before the cold sets in. I have got enough time this morning to get it done at a relaxing pace. No stress!